V-Glace

V-Glace The “World’s First” CAE software

About V-glace

[Glass Mold Simulation CAE Software]

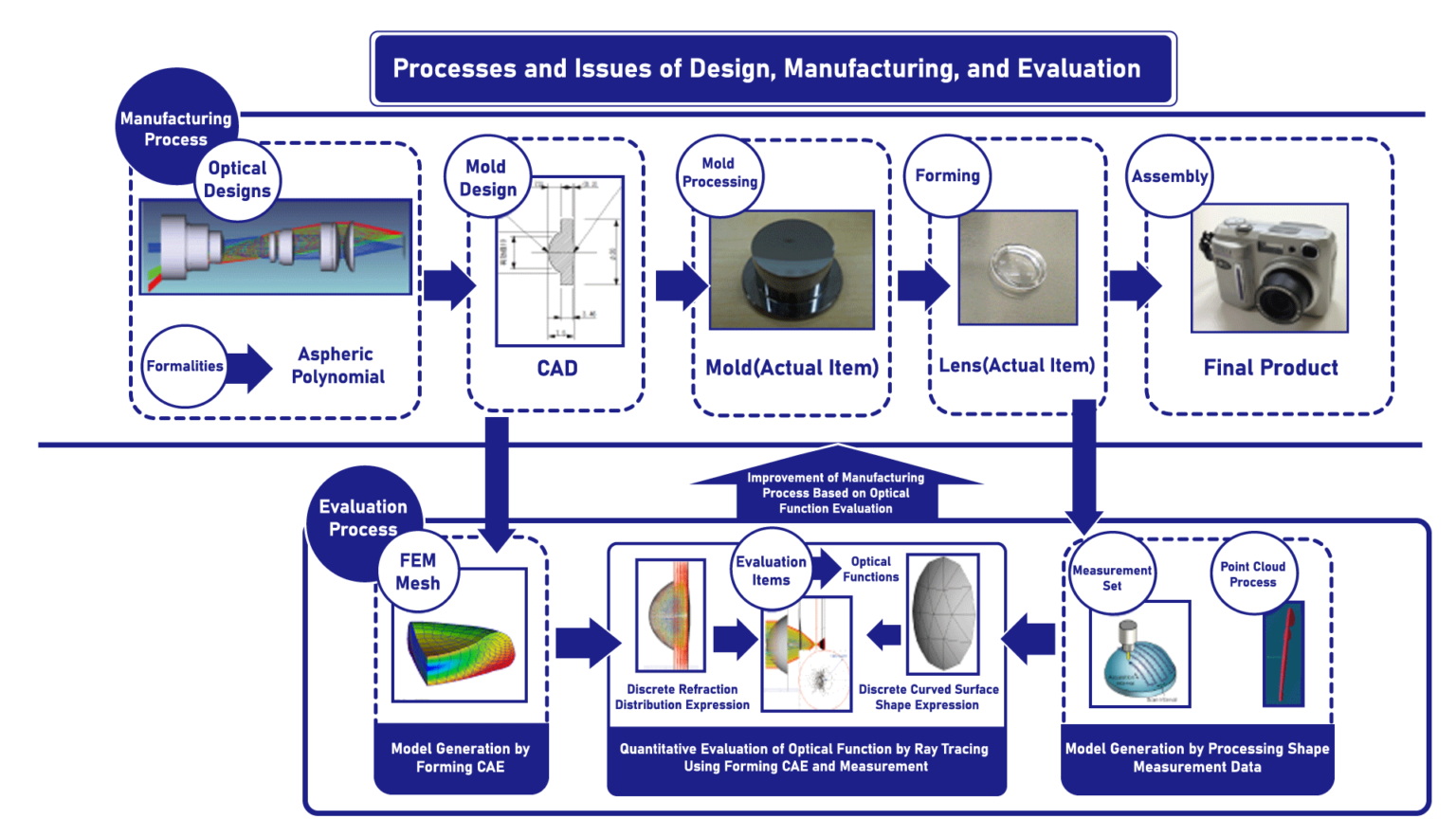

The “World’s First” CAE software that can simulate the process of glass mold forming by incorporating glass properties, developed in collaboration with RIKEN. 3D simulation of the glass mold forming process using V-Glace enables process optimization and results analysis.

V-Glace

The software can perform stress analysis, heat transfer analysis, structural relaxation analysis, and viscoelastic analysis of molds and glass during the pressing process at high temperatures.

In particular, it can be used as a guideline for process optimization because it can output virtual temperatures that serve as an indicator of changes in the glass state during the cooling process. As a result, the intuition and experience of skilled workers and the behavior of samples in the mold, which until now have been a black box, can be quantified, contributing to improved quality and productivity through the accumulation of know-how.

Shorten Development Period and Reduce Costs

By performing a simulation before mold design, it is possible to predict correction points such as molds, molding conditions, and preforms. As a result, the number of mold modifications and prototypes can be reduced, contributing to shorter development times and lower costs.

Simulation Samples

We present four sample simulations.It is possible to analyze the heat transfer, shape change, stress time changes, of the glass material in the mold with animation.This allows us to observe the differences in glass material behavior caused by differences in preform geometry and molding patterns.

*Sample shows 1/4 of the whole

Convex Lens

Meniscus Lens

Smartphone Cover Glass

Micro Lens Array

Molding Consultation

We provide consultation on mold shapes, preform shapes, molding process conditions, and other factors to ensure stable production, proposing optimization of the molding process.

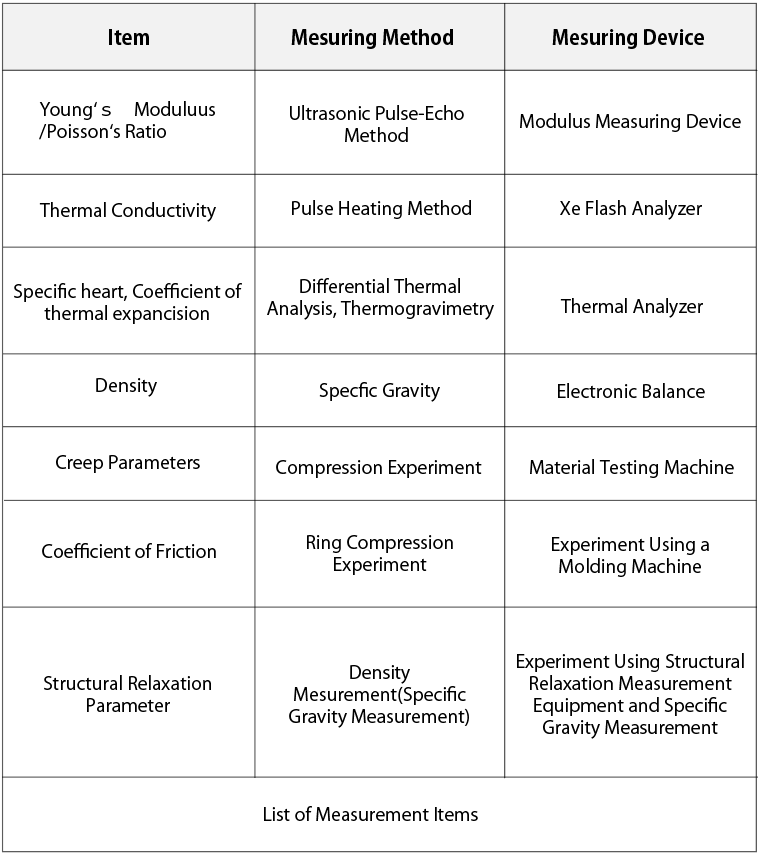

MEASUREMENT OF PHYSICAL PROPERTIES

It measures and records the physical property values of samples used in simulations, thereby contributing to more accurate simulations. This includes parameters such as creep, friction coefficient, and structural relaxation, which are essential for the simulations.

Software Environment

Operating System

Windows10 or more

CPU

Intel CPU (Core i series,)

AMD CPU (Ryzen series)(6 cores or more is recommended, multi socket compatible)

Memory

16GB or more is recommended

HDD

1GB (installation area, 500MB or more data area)

Dispaly

FHD (1920 x 1080) or more recommended

Others

3 USB ports are required for USB dongles.

(a USB hub can be used)

About Company

Company name

Integration Technology CO.,Ltd.

CEO

Hiroyoshi Funada

Main Office

Inomata Building (301) 16-2,Honchou,Wako-shi,Saitama,351-0114 JAPAN

Tokyo Office

2F Tomioka Wakura Building , 1-18-17 Tomioka , Koto-ku, Tokyo 135-0047

Location of joint research

2-1, Hirosawa, Wako, Saitama 351-0198, Japan 351-0198 , (RIKEN Research Exchange Building W414)

Telephone number

[Main Office: Wako] 048-486-9605

[Tokyo Office] 03-6264-8312

Shareholder

Hiroyoshi Funada

Advamced Simulation Technology of Mechanics R&D Co., Ltd.

NEXTY Electronics Corporation

Saitama Resona Bank,Limited

TechnoPro, Inc.

Establishment

July 1, 2011

Certification

RIKEN Venture(August 2011)

Contact Us

main office

Inomata Building (301) 16-2,Honchou,Wako-shi,Saitama,351-0114 JAPAN

tokyo office

2F Tomioka Wakura Building , 1-18-17 Tomioka , Koto-ku,Tokyo 135-0047